A polycrystalline diamond is made of quality diamond powder sintered at a high pressure and temperature with cobalt, nickel, or other alloy as the sintering agent. Featuring a high-density rigid skeletal organizational structure formed by direct bonding between the grains, a diamond thus produced is 5 to 20 times more wear resistant than a polycrystalline diamond with silicon as bonding. Obviously advantageous in strength, hardness, impact resistance, etc., it is very suitable for making drawing dies or grinding and cutting tools for drawing nonferrous metals. In the drawing process, rough grains will result in a long service life while fine grains will lead to a smoother finish. HMR has attained a high level in the industry in terms of granularity. It can produce a polycrystalline diamond with a granularity of 1µm, which makes it possible to make dies that can come up with better-quality products faster.

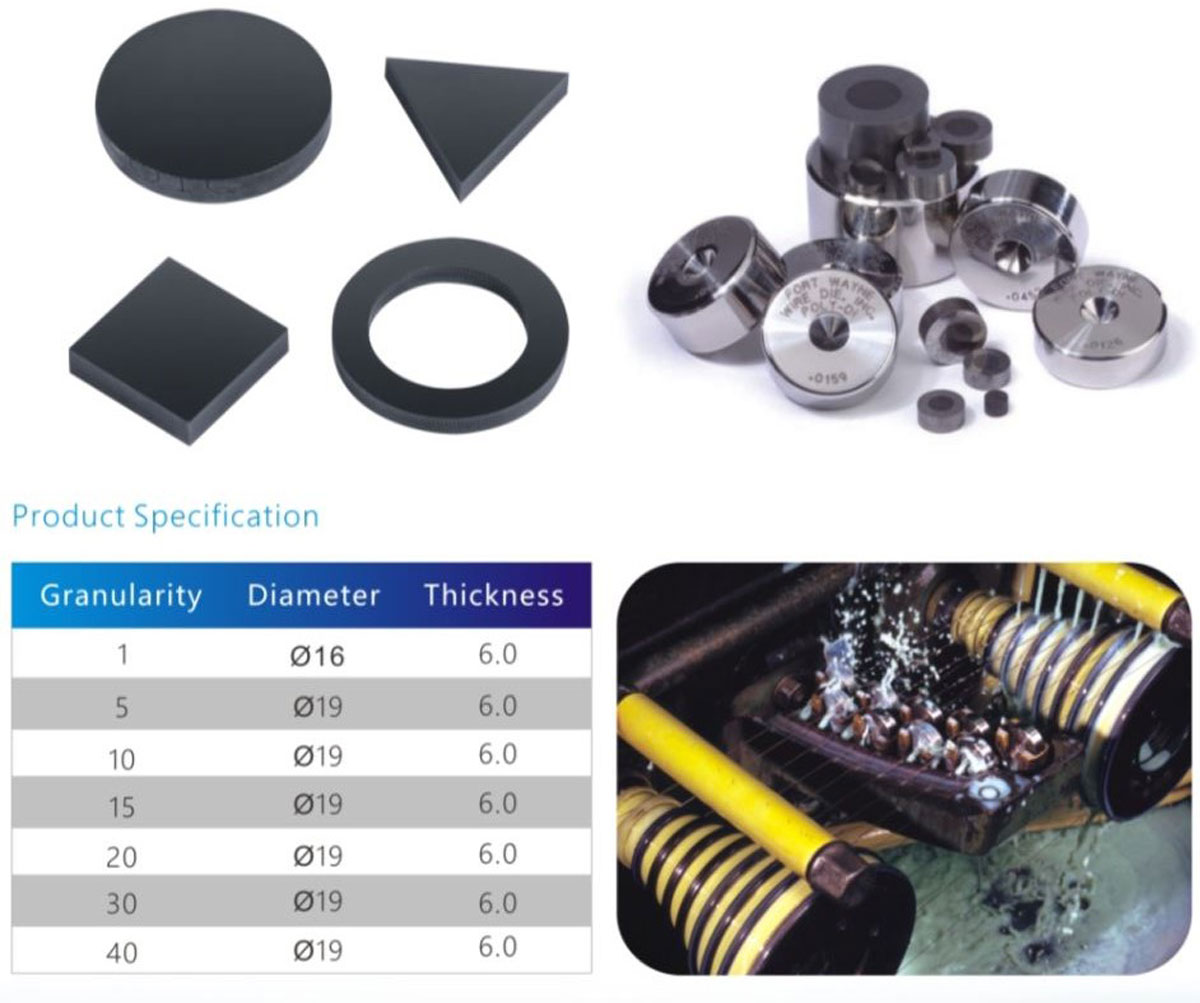

The company has polycrystalline diamonds with granularities ranging from 1-40µm available for customers to choose from.